CONTRACT WORK SERVICES

State-of-the-art technology is the key to quality sheet metal working

CONTINUOUS DEVELOPMENT

NEW HORIZONS

√ Our contract work services allow our clients to enhance their capacity and reduce their delivery times.

√ Our company is engaged in sheet metal processing by using the most up-to-date technologies, e.g. laser cutting ensures the most precise sizing and cutting of metal sheets.

√ It is extremely important for us to provide the highest possible quality for our clients. Therefore we are continuously developing our machine fleet, and provide professional and further trainings for our employees.

√ In recent years we have invested in several new special equipment, robotic cells.

√ With the up-to-date robotic cells in mind we are looking for new horizons, opening up more and more to international contract working.

√ Our newly built plant is also supporting our goals.

WHAT MATERIALS WE WORK WITH?

METAL - ANY METAL

We work with carbon steel, stainless steel, acid resistant steel, galvanised and aluminum sheets.

We offer several services in the field of sheet metal processing for our business partners on a contracted work basis.

LASER CUTTING

√ Laser cutting is one of the most precise and most enabling technologies in the field of metal sheet processing and shaping.

√ The laser cutting device works with extreme accuracy, it is able to cut the desired shape out of any material or cut workpieces of different thickness.

√ Our modern laser cutting equipment enables professional laser cutting, plate sizing or working on metal components with varied geometries.

PIPE BENDING

√ Our pipe bending machine represents the most modern technology, and by being computer controlled it is able to work in 3 dimensions.

√ Our pipe bending machine saves significant labor costs and expenses, as it is able to bend various 3D CNC pipes from any metal material. We also cut pipe parts.

√ Maximum diameter of the base material: 76 mm L = 6000 mm.

Parameters of our pipe bending equipment:

CNC-controlled 3D pipe bending machine – bending is up to Ø 76 mm or 6000 mm long

EDGE BENDING

√ Our modern edge bending equipment is able to bend acid-resistant, stainless, structural steel, aluminum, LINDAB, etc. materials.

A given technical drawing enables us to make plate setting, or even the drawing can also be made on the finished product.

√ Edge bending equipment parameters:

Bending length: 3500 mm from 0.5 to 15 mm, depending on the bending length.

Compact Industrial Robotic Bending Cell enables us to produce large quantities of the same part, AND all with the same high quality.

See below how it works! ⇓

COMPACT ROBOTIC

BENDING CELL

Our machine has a high-speed Dyna-Press 40T Pro electric edge bending press brake and an industrial robot is connected.

This compact, integrated unit allows the automation of bending for the small and medium-sized parts in varying batch sizes at the speed of up to 25 mm / second.

Dyna-Cell offers maximum bending productivity over a compact 5 m x 5 m floor area.

MAIN CHARACTERISTICS

〉It has a unique gripper that fits the part size – it can grip 400mm x 350mm part – the minimum width of the part is 40mm – the weight is up to 3 kgs;

〉Bending speed is up to 25 mm / second;

〉It works with a bending force of 40 tons;

〉Maximum bending length is up to 1500 mm;

Only works with metal – stainless, aluminum, carbon steel, galvanised sheet –;

Easy-Form® laser system – EFL – aka the laser angle correction system guarantees the desired angle – from the first bending operation.

√ As of EFL the bending process is never interrupted, production time is not lost.

√ The EFL system allows the machine to adapt to material variations – such as plate thickness, strain hardening and grain direction – in order to automatically compensate for any changes.

√ LARGE QUANTITY OF IDENTICAL PARTS

√ SAME HIGH QUALITY

√ OPTIMAL COST – BENEFIT RATIO

THE SOLUTION =

COMPACT

ROBOTIC BENDING CELL

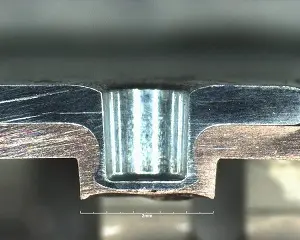

INJECTION (PEM)

A common application of PEM fasteners is pressing into sheet metal.

You can choose the fastener that best suits the application from nuts, pins, spacers, and captive screws with different materials and surface treatments.

Advantages:

✓ No fasteners at all or just fewer parts are needed

TOX TECHNOLOGY

Using the TOX process, the high-energy spot welding process can be triggered.

The TOX process can also be used perfectly in conditions where there is little or no spot welding available.

INSERTING RIVET NUTS

√ Insertion of rivet nuts up to M3 – M8

√ Driving of stainless steel, galvanised threaded studs up to M3 – M8

WELDING

√ AFI, AWI welding of aluminum and stainless steel structures and pipes;

√ TÜV CERT qualified welders;

√ Spot welding of galvanised, aluminum and stainless steel plates with NC controlled spot welding equipment;

The Industrial Robotic Welding Cell enables us to produce large quantities of the same part, AND all with the same high quality.

See below how it works! ⇓

INDUSTRIAL ROBOTIC

WELDING CELL

Fronius Fanuc welding robot

A versatile robot that handles productivity over a wide range of jobs

√ The welding cell is equipped with two 1-axis workpiece rotators.

√ The robot moves on a 5m travel path placed between the requested rotating equipment, parallel to the length of the table.

√ Only one of the two rotating devices is welding at a time, on the other side the operator removes the welded part from the rotating device and prepares the next workpiece.

√ The device is equipped with manual clamps.

√ The robot has a seam search function that automatically detects individual points on a large part and corrects the program according to the measurement.

√ The CMT function supports the machine in making a cleaner seam.

√ The welding cell is surrounded by a protective fence and a sunscreen curtain.

√ In front of the rotating equipment, a light censor gate controls the operator’s access to the rotating workspace.

FRONIUS TPS400I CMT DIGITAL WELDING MACHINE

√ High productivity, high welding speed, constant fusion depth and quality;

√ Magnetic impact protection for the gun with a recovery accuracy of 0.05 mm;

√ Remote diagnostics, saving and documenting welding parameters';

√ Procedures: MIG-MAG standard;

FANUC ARC MATE 120ID ROBOT ARM

√ 6-axis robot with integrated welding work cable;

√ Internal cable routing for easier use, better access and longer cable life;

√ Load capacity: 25 kg;